HPLC Principle & Instrumentation

High performance liquid chromatography (HPLC) is basically a highly improved form of column liquid chromatography to provide high accuracy and high sensitivity analyses to find out purity and impurity for the non-volatile substance. Instead of a solvent being allowed to drip through a column under gravity, it is forced through under high pressures of up to 400 atmospheres. That makes it much faster.

PRINCIPLE

Chromatography is the separation technique in which solutes get separated based on the difference in the extent to which they are partitioned between stationary phase and mobile phase. All chromatographic separations, including HPLC operate under the same basic principle; separation of a sample into its constituent parts because of the difference in the relative affinities of different molecules for the mobile phase and the stationary phase used in the separation

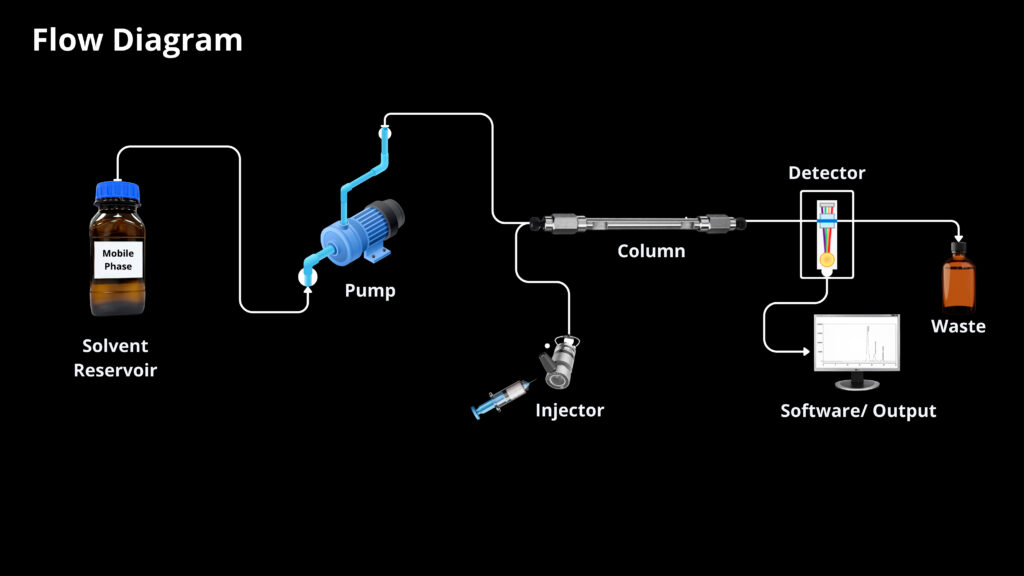

INSTRUMENTATION

- A reservoir holds the solvent (called the mobile phase, because it moves).

- A high-pressure pump (solvent delivery system or solvent manager) is used to generate and meter a specified flow rate of mobile phase, typically millilitres per minute.

- An injector (sample manager or autosampler) is able to introduce (inject) the sample into the continuously flowing mobile phase stream that carries the sample into the HPLC

- The column contains the chromatographic packing material needed to effect the separation. This packing material is called the stationary phase because it is held in place by the column hardware, a column oven.

- A detector is needed to see the separated compound bands as they elute from the HPLC column (most compounds have no colour, so we cannot see them with our eyes). The mobile phase exits the detector and can be sent to waste, or collected, as desired.

- When the mobile phase contains a separated compound band, HPLC provides the ability to collect this fraction of the eluate containing that purified compound for further study. This is called preparative chromatography.

PARTS OF HPLC

1. MOBILE PHASE

Mobile phase is the most important parameter in HPLC. Type of mobile phase used may have a big effect on the retention. It can promote or suppress an ionization of the analyte molecules, and it also can shield an accessible residual silanol or any other active adsorption centres on the adsorbent surface.

The objective of using different solvent mixtures is to achieve the desired polarity of mobile phase for complete miscibility of the sample and control interaction of sample components with the stationary phase to achieve the desired degree of resolution of separated component peaks in the shortest possible time.

In order to meet the required objectives, the mobile phase should have the following essential features:

The two operational modes commonly used are:

Isocratic mode: in the Isocratic mode the composition of the mobile phase remains constant throughout the analytical run, i.e., the proportion of solvents in the mixture is pre-decided and remains unchanged during analysis

Gradient Elution: the composition is varied by the software through the analytical run in a predetermined mode and at the end of the run the proportion of solvents is different from the initial proportion.

- The sample should be fully soluble in the mobile phase. Any insolubility will result in flow Always check sample solubility in mobile phase before injection into the system.

- Mobile phase components should be non-hazardous and non-toxic. They should not pose any health hazard to the operator.

- Mobile phase should be inert towards sample constituents and the stationary phase. Any reactions can lead to formation of insoluble suspensions which can result in column blockages.

- The mobile phase should not give its own response on passing through the detector. In other words the detector signals should reflect only the response of the sample constituents. This, however, is not applicable in bulk property detectors such as refractive index detector which respond to overall changes in refractive index of the mobile phase containing the eluting

- The mobile phase should be affordable and the proportion of solvents used should make the analysis economically

- The mobile phase should be filtered with 45 µ (or smaller size) filter and degasses properly.

2. PUMP

As the name, HPLC i.e. high-performance liquid chromatography indicates, one needs to generate pressure. HPLC pumps generate pressure on the solvent so as to pass through the dense column. Since the column particles are very small, the surface area is high and even separation is efficient. But the pressure required for the mobile phase to flow is very high. So pumps able to generate such high pressure are needed in HPLC.

In general, the operable pressures in HPLC are 500 to 5000psi.

In UPLC, i.e. Ultra-pressure liquid chromatography the pressure might go up to 10,000 psi or even more. So the HPLC pumps must be tough to generate such high pressures.

As a general rule, HPLC pumps used should suffice some requirements like

- Generate sufficient pressure generation through the column,

- Suitability to the wide range of solvents used,

- create uniform pressure without fluctuations

- deliver constant flow rate e. the volume of solvent pumped per minute

- easy to use and operable for long duration

- Less cumbersome and smaller in size to fit the

- also preferably

Based on these requirements of HPLC pumps, there are of three types like

- Screw-driven syringe pump

This pump works by producing a pulse-less delivery. And by this, the flow rate of the mobile phase is very well controlled. They are suitable for isocratic mobile phase HPLC run. isocratic means using the same mobile phase or single solvent throughout the run. They have their limitations like small injection volume. Also one cannot use them to run gradient mobile phases i.e. multiple mobile phases as a mixture in a single run.

b. Reciprocating pumps (piston pump)

As the name indicates, the pump has two or more pistons. This is the most common and widely used pumps. Here the mobile phase is pushed due to back and forth action of pistons present about a cylindrical chamber. It is widely used due to the following reasons.

- Good pressure

- Constant flow

- Useful for both gradient and isocratic

- Space occupancy is

Reciprocating pumps are used in most of the instruments. They are used as a single pump or dual or multiple pumps to meet the needs of the analysis like isocratic or gradient elution etc. They are present in most advanced instruments so they are controlled by software. The pressure, rate of flow of mobile by the pump are regulated by software making it hassle-free.

c. Pneumatic pumps

As the name indicates (pneumatic) there is the use of gas to pressurize the mobile phase present in a collapsible solvent container. They have some advantages like low-cost or inexpensive to purchase, pulse-free and also simple. But are not widely used due to disadvantages like low- pressure generation, low capacity to dispel the mobile phase and also the pumping rate varies with the viscosity of the mobile phase used.

3. INJECTOR

HPLC injection is a technique used to load the sample into the HPLC system. This process is done using a specially designed injection system which is a separate and prominent part of the HPLC system.

HPLC injection has certain requirements:

- The volume of injection for all the samples under an experiment should be the

- The injection volume is minimal so, it should be in the range of

- The sample injected should be free of any particulate

- The injection sample should have no air

- The HPLC injection is always done when the mobile phase is kept under a constant flow rate through the column.

a. Rheodyne injector or loop injector as HPLC injection system:

The most popular injector is the rheodyne injector.

This is the injection system used widely in HPLC. The system has a load mode and an inject mode. In injecting mode, the sample from a syringe is injected into the loop. Then the injection is set to inject mode where the loaded sample is left into the flow of HPLC mobile phase. Any excess sample is transferred to drain. The system has loops of fixed volume like 20μl, 50μl, 100μl, and 200μl. So when a sample of 25 μl is injected into a loop of 20μl, then only 20μl is passed into the column and remaining is drained out. The software in the computer has to be set for the injection phase. Then load and inject samples are specified to record the readings of that injection.

b. External HPLC syringe for HPLC injection:

Mostly needles in microliter (μl) range are used. For this specifically designed Hamilton syringes are used. These syringes are to be handled carefully as they are easily prone to damage by accidental fall, particulate matter, etc.

Further, before and after use, these syringes have to be cleaned with methanol and HPLC grade water. This will prevent the injection from clogging and damage due to any material inside the column of the syringe.

c. Auto sampler:

There the system takes the exact volume of the sample from a prefixed vial and injects into the column. The software controls the whole process of injection, pump pressure and detector.

For auto-injector machines, manual cleaning of syringe is not required unless the instrument is not used regularly. So during the HPLC method, the injection system should be checked and cleaned to see that it functions properly.

4. COLUMN

Column is expressed as 250 x 4.6 mm, 5µm and with sign of an arrow

Where, 250 mm is length,

4.6 mm is inner diameter of the column

5µm stands for particle size of the stationary phase

shows the flow direction.

HPLC columns range from 20 mm to 500 mm in length [L] and 1 mm to 100 mm in internal diameter [i.d.].

Types of packed gels in HPLC columns

- Silica gel

Silica gel is the most popularly used packing material. Silica, silicon dioxide, has the chemical formula of SiO2. The silica gel used in LC has pores on the surface of the gel. By having the pores, it provides larger surface area compared to the ones without pores. The size of pore is very small and expressed in angstrom (Å) unit.

b. Polymer gel

In the earlier stage of HPLC development, almost always silica gels were used. However, polymer- based column is becoming popular. The generally known polymers include polyethylene and poly propylene. Shodex columns use several different types of polymers as listed below.

- Polystyrene (Styrene divinylbenzene copolymer)

- Polymethacrylate

- Polyhydroxy methacrylate

- Polyvinyl alcohol

Similar to the silica gel, the polymer gel is manufactured into very small particles.

c. Other gel

Other than silica and polymer gels, the gels used include natural substances such as cellulose, agarose, dextrin, and chitosan, and members of ceramics such as hydroxyapatite and zirconia. However, their use is very limited.

Types of separation mode

As explained earlier, there are many different types of “traps” in the column, and depending on the “trap” there are different types of columns. This “trap” is called separation mode. Generally used separation modes in LC are listed below.

- Reversed-phase (RP) mode

- Normal-phase (NP) mode

- Hydrophilic Interaction (HILIC) mode

- Ion exchange (IE) mode

- Ligand exchange mode

- Ion exclusion mode

- GPC mode

- GFC mode

- Multi mode

- Affinity mode

- Chiral mode

HPLC Column Hardware

A column tube and fittings must contain the chromatographic packing material that is used to effect a separation. It must withstand backpressure created both during manufacture and in use. Also, it must provide a well-controlled (leak-free, minimum-volume, and zero-dead-volume) flow path for the sample at its inlet, and analyte bands at its outlet, and be chemically inert relative to the separation system (sample, mobile, and stationary phases). Most columns are constructed of stainless steel for highest pressure resistance. PEEK™ [an engineered plastic] and glass, while less pressure tolerant, may be used when inert surfaces are required for special chemical or biological applications.

5. DETECTOR

The actual separation of each component in the sample is carried inside a column; however, this separation needs to be “collected” for us to be able to see it. The detectors are used for this purpose. The separated components are monitored and expressed electronically. There is no universal detector that can monitor all compounds and there are many detectors used for LC analysis. Some are listed below.

1. UV, VIS, and PDA Detectors

The UV, VIS, and PDA (Photo Diode Array) detectors are categorized as absorbance detectors. They provide good sensitivity for light-absorbing compounds at ~pg level. They are easy to operate and provide good stability. UV detector is a very commonly used detector for HPLC analysis. During the analysis, sample goes through a clear color-less glass cell, called flow cell. When UV light is irradiated on the flow cell, sample absorbs a part of UV light. Thus, the intensity of UV light observed for the mobile phase (without sample) and the eluent containing sample will differ. By measuring this difference, the amount of sample can be determined. Since the UV absorbance also differs depend on what wavelength is used, it is important to choose an appropriate wavelength based on the type of analyte.

A standard UV detector allows user to choose wavelength between 195 to 370 nm. Most commonly used is 254 nm. Compared to a UV detector, a VIS detector uses longer wavelength (400 to 700 nm). There are detectors that provide wider wavelength selection, covering both UV and VIS ranges (195 to 700 nm) called UV/VIS detector. PDA detects an entire spectrum simultaneously. UV and VIS detectors visualize the obtained result in two dimensions (light intensity and time), but PDA adds the third dimension (wavelength). This is convenient to determine the most suitable wavelength without repeating analyses.

2. Refractive-Index Detector

RI detector measures change in reflex index.

RI detector has lower sensitivity compared to UV detector, and that’s the main reason why RI is not as commonly used as UV. However, there are some advantages over UV detector. It is suitable for detecting all components. For an example, samples which do not have UV absorption, such as sugar, alcohol, or inorganic ions obviously cannot be measured by a UV detector. In contrast, change in reflective index occurs for all analyte, thus a RI detector can be used to measure all analyte. It is applicable for the use with solvent that has UV absorbance. A UV detector cannot be used with solvent which has UV absorbance. Intensity observed by a RI detector is comparable to the concentration of analyte. Because of those advantages, RI is often used for the detection of sugars and for SEC analysis.

3. Evaporative Light Scattering Detector

ELSD provides good sensitivity for non-volatile analytes at ng level. The column effluent is nebulized and then evaporated to make it form fine particles. The analyte is then radiated with a laser beam and the scattered radiation is detected. The target sample includes lipids, sugar, and high molecular weight analytes. It is used in the similar way as a RI detector, but can provide more sensitive detection with stable base line. Another advantage is that ELSD can be used for the gradient method whereas RI cannot.

4. Multi-Angle Light Scattering Detector

For the SEC analysis, MW of analyte is estimated from the calibration curve drown using a set of known standards. However, by using a MALS, MW can be determined directly without the need of calibration curve. Also, MALS can provide an absolute MW of the analyte with very low detection limit.

5. Mass Spectrometer

The analytes are detected based on their MW. The obtained information is especially useful for compound structure identification. However, its use is not limited to structure identification and can be used to quantify very low detection limit of elemental and molecular components.

6. Conductivity Detector

Solutions containing ionic components will conduct electricity. Conductivity detector measures electronic resistance and measured value is directly proportional to the concentration of ions present in the solution. Thus, it is generally used for ion chromatography.

7. Fluorescence Detector

The advantage of fluorescence method is its high sensitivity for selective groups of compounds at ~fg level. By using a specific wavelength, analyte atoms are excited and then emit light signal (fluorescence). The intensity of this emitted light is monitored to quantify the analyte concentration. Most pharmaceuticals, natural products, clinical samples, and petroleum products have fluorescent absorbance. For some compounds which do not have fluorescence absorbance or low absorbance, they can be treated with fluorescence derivatives such as dansylchloride. The system is easy to operate and relatively stable.

8. Chemiluminescence Detector

Similar to FL, but instead of using a light source to excite the analyte atoms, the excitation is initiated by chemical reaction. Since it is not relied on the external excitation source, the noise is small, results in high signal to noise ratio, i.e. it provides even higher sensitivity than FL.

9. Optical Rotation Detector

Specific for the optical isomer measurement. The column can separate R- and L- type optical isomers, but the general detectors (e.g., UV) cannot distinguish which is R nor L. OR detector provides this information.

10. Electro Chemical Detector

There are several different types of ECs. The detection is based on amperometry, polarography, coulometry, and conductometry. They offer high sensitivity, simplicity, convenience, and wide-spread applicability. It is especially suitable for the use with semi-micro or capillary type system.